ABB机器人的变位机

发布日期:2012-12-07 兰生客服中心 浏览:8697

第一节:ABB机器人的变位机

ABB提供全方位的工件定位,不论是编程期间还是运行期间,都确保各轴均与机器人完全协调一致。变位机配有简单明了的编程说明,使用十分方便。变位机的驱动系统和软件均与机器人相同。

动态软件(HPP,即高性能变位机)可自动补偿重力、惯性力以及摩擦力的影响,以确保能够按照程序设定路径快速而精确地运行。相关计算由机器人软件Load Id负责完成。变位机的作用是在弧焊、热切割及其它相关应用中对工件进行操纵。

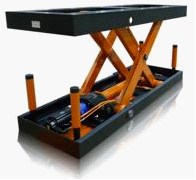

1、FlexLifter:IRF 600, IRF 100 & IRF 190

FlexLifter垂直升降机用于精确升降工件。配套FlexTrack,可构成生产线上的升降移送系统。

• 防护周全

FlexLifter的传动链采用密闭防护,适用于严苛的工业环境。

• 性能卓越

FlexLifter的性能特征与ABB机器人相同,具有优异的重复定位精度,在最大荷重下也能确保定位的可靠无误。

• 安装简单,维护方便

FlexLifter经精心设计,安装简单、便于维护。电机检修方便,需维护的零部件数量极少。

• 基于机器人的技术

FlexLifter与ABB机器人一脉相承,采用基于IRC5机器人的技术,无需配套专用软件,也不必开展专门培训。其通用界面为机器人程序员和维护人员所熟悉,无需准备即可上手操作。

FlexLifter的升降速度、加速度及顶板停止位均可编程设定,是一种适用广泛的智能化升降系统。

• 选件

FlexLifter采用模块化设计,提供不同荷重数种机型。升降机内部还可集成回转单元,视操作需要进行工件旋转。全套升降机单元既可独立安装于地面,也可固定在FlexTrack顶部。

2、FlexPLP Linear IRPLP

FlexPLP Linear是一款完美的可编程线性变位机。

FlexPLP Linear(可编程线性变位机)是一组可编程线性轴,组合后可构成小型的一至三轴线性机器人。FlexPLP通常用于携带工装并进行变位,以配合同一夹具夹持的不同工件。

各轴可同步配合运行,形成一套可编程工装系统。

• 防护周全,结构紧凑

FlexPLP的一大特点是传动链与内部缆线均采取周全的防护措施,是严苛工业环境中的理想解决方案。

FlexPLP带有可伸缩垂直轴,尽最大可能减小对夹持件的干扰。

• 性能卓越

FlexPLP的性能特征与ABB机器人相同,具有优异的重复定位精度,能确保工装的几何定位可靠无误。

FlexPLP结构极其刚稳,在荷重下也能保持几何精度,可媲美固定式工装。

• 安装简单,维护方便

FlexPLP经精心设计,安装简单、便于维护。各轴分别设检修盖,拆下即露出整条传动链。一旦设备失灵,可方便地将故障轴与其他轴分离,并在数分钟内完成更换。

• 基于机器人的技术

FlexPLP与ABB机器人一脉相承,采用基于IRC5机器人的技术,无需配套专用软件,也不必开展专门培训。其通用界面为机器人程序员和维护人员所熟悉,无需准备即可上手操作。

FlexPLP的输送速度、加速度及轴停止位均可编程设定,是一种适用广泛的智能化工装系统。

• 选件

FlexPLP采用模块化设计,可根据需求任意组合一至三轴。FlexPLP的集成式IO信号线和空气管线在轴顶板设有接口,为连接顶部的夹具等工艺设备提供了便利。

3、IRBP A

This positioner is for workpieces that have to be rotated around two axes to reach best process position. It is suitable for applications requiring one or two stations .

The positioner IRBP A comes in three variants and is designed to handle workpieces incl. fixture up to 750 kg. This positioner has a fixed table.

The modular design, few and heavy-duty moving parts as well as minimal maintenance demands make the IRBP A very service friendly.

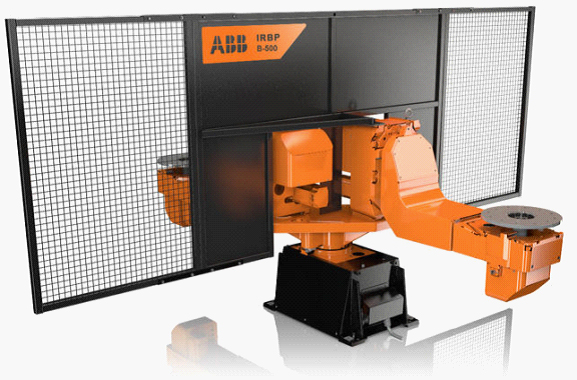

4、IRBP B

This positioner features a twin station solution where the robot works on one side and the operator can load and unload on the other side. A screen is fitted between the two stations to protect the operator from arc-eyes.

The positioner IRBP B comes in three variants and is designed to handle workpieces incl. fixture up to 750 kg. It is ideal for workpieces that have to be rotated around two axes to reach the optimal process position.

The modular design, few and heavy-duty moving parts as well as minimal maintenance demands make the IRBP B very service friendly.

5、IRBP C

This positioner features a twin station solution where the robot works on one side and the operator can load and unload on the other side. The workpiece is fixed and cannot be manupulated during the process. A screen is fitted between the two stations to protect the operator from arc-eyes.

The positioner IRBP C comes in two variants and is designed to handle workpieces incl. fixture up to 1,000 kg.

The modular design, few and heavy-duty moving parts as well as minimal maintenance demands make the IRBP C very service friendly.

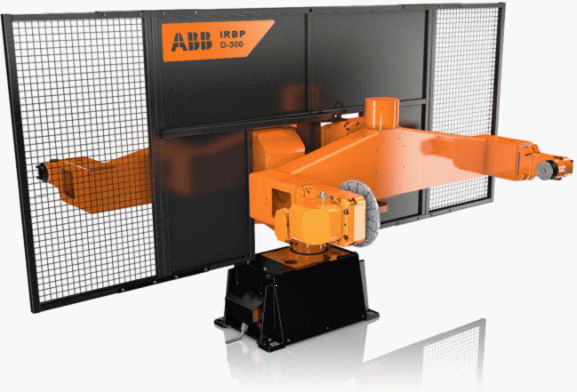

6、IRBP D

This positioner features a twin station solution where the robot works on one side and the operator can load and unload on the other side. A screen is fitted between the two stations to protect the operator from arc-eyes.

The IRBP D positioner, which comes in two versions, is designed to handle workpiece loads incl fixture up to 600 kg. It is suitalble for applications where the workpiece has to be rotated around two axes and a supporting tailstock is needed.

The modular design, few and heavy-duty moving parts as well as minimal maintenance demands make the IRBP D very service friendly.

上一篇:KUKA机器人的工件变位机

下一篇:ABB机器人旋转关节的上紧

-

KUKA机器人的工件变位机

第二节:KUKA机器人的工件变位机 KUKA机器人的工件定位装置每种自动化解决方案的目标都是提高生产效率及质量。借助KUKA Posiflex System您可在任何位置实现这一目标 — 因为它可以迅速精确地校准部件。对于例如自动化气体保

2012-12-07 -

ABB的机器人导轨系统

第一节:ABB的机器人导轨系统 ABB导轨系统(Track Motion)的设计宗旨是确保机器人的效能得到充分而可靠的发挥,实现客户自动化投资价值的最大化。机器人导轨能够极大地延伸机器人的工作覆盖范围,使一台机器人能够同时服务于多台设备,

2012-12-07 -

KUKA的机器人导轨

第二节:KUKA的机器人导轨 KUKA线性滑轨能够确保整条生产线上的生产效率最大化。有了库卡线性滑轨,作业空间将显著增大。另一项重要优势: 线性滑轨以附加轴的形式工作 — 因此无需附加的控制系统。 库卡产品系列涵盖所有负载级别、所有环境

2012-12-07 -

马丁路德快速定位夹具

第一节:马丁路德高精度快速定位夹具系列 标准型系列 ● PCS系列产品马丁路德PCS系列产品广泛应用于精密机械加工和模具制造。适合于零件:尺寸100×100×50mm工件,重复定位精度0.002mm。适合于设备:电火花机、加工中

2012-12-14